Automatic (As-Rs) Rack Systems

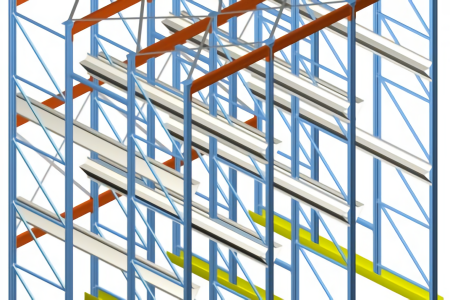

Heavy Duty Rack Systems

- Our Heavy Shelf System products are made of St 37, St 44 and St 52 standard steel material.

- Thickness of produced profiles is 1,5 mm, 2 mm, 2,5.mm and 3mm.

- Table sheet thickness is 1,2 - 1,5 and 2 mm the material is DKP SHEET and GALVANISED materials.

- Carrier traverses are produced in St 37 material and they have different color options subject to their weight.

(Their thickness is CC80-100-120-140-160) 1,5mm and 2mm)

Our Heavy Duty Racking uprights and traverses are constructed from hot-rolled structural steel sections, which make them very robust and able to withstand the rigours of the most arduous industrial environments.

All our racking systems designed fulfill requirements of FEM standards. Accessories, safety features, different traverses, metallic shelves allow for the racking to be customised to suit specific storage needs.

When your warehouse management cannot cope with heavy loads, Eren Grup Heavy Duty Racking systems offer an ideal, cost-effective and safe storage solution for various types of heavy products. It is a standard pallet racking configuration yet is capable of carrying far heavier loads of up to 20 tonnes and more over a 3-meter span.

Available painted in any colour. A galvanised finish is recommended for external applications and cold stores.

- There are various designs available depending upon the product type being stored.

- We offer a full project management service, including installation

Light Duty Rack Systems

It is a practical rack system that allows easy storage of products with low weights and dimensions.

Due to the easy assembly of the horizontal carriers (traverses), it is easy to adjust the rack cells according to the product dimensions.

Due to the lightweight rack system that provides ease and speed of manual loading, besides an aesthetic appearance, the area to be installed is used with maximum efficiency.

Light Duty Racking System, which offers the possibility of narrowing and expanding later, provides economical and practical opportunities..

'Stored (Mezzanine) Shelving Systems', 'Alternative Light Shelving Systems', 'Boxed Sliding Shelving Systems', 'Archive Shelving Systems' and 'As/Rs Shelving Systems for Boxes' options can be preferred according to the area information and purpose of use.

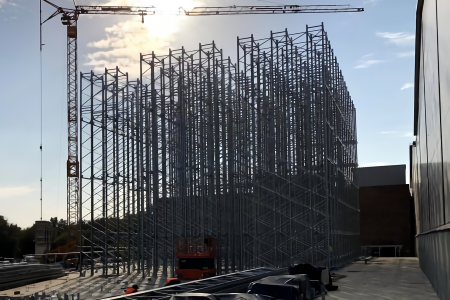

Automatic (As-Rs) Rack Systems

Automatic (AS-RS) Heavy-duty racking systems are Smart Warehouse applications where storage operations are done entirely with a computer system.

The most important feature of these shelving systems is that they consist of high-level warehouse shelves. With this system, shelves up to 40 meters high can be controlled. Each point in the warehouse area is fulfilled by barcodes and sensors through computer programs.

Advantages;

- Automatic (AS-RS) Heavy-duty racking systems, obtained by computer control, provide a fast process in the storage unloading area in cases such as taking up maximum space in the warehouses. With this feature, it also eliminates problems such as insufficient storage.

- Automatic (AS-RS) Heavy-duty racking systems can be used effectively for all production branches. In terms of design, these shelf systems can be made in different sizes and dimensions according to the quantity of the products.

- In this storage system, shelving systems enable the creation of the highest warehouse opportunities due to the unmanned operation of the computer channel.

English

English

Türkçe

Türkçe

Teknolojik değişim ve yenilikleri takip ederek, sürekli gelişim ve mükemmeliyeti temel alarak, yüksek kalite standartlarında üretim yapmak, her zaman ve her yerde

müşterilerimize en uygun, en kaliteli, en ekonomik ve en doğru çözümleri sunmaktır.

Teknolojik değişim ve yenilikleri takip ederek, sürekli gelişim ve mükemmeliyeti temel alarak, yüksek kalite standartlarında üretim yapmak, her zaman ve her yerde

müşterilerimize en uygun, en kaliteli, en ekonomik ve en doğru çözümleri sunmaktır.