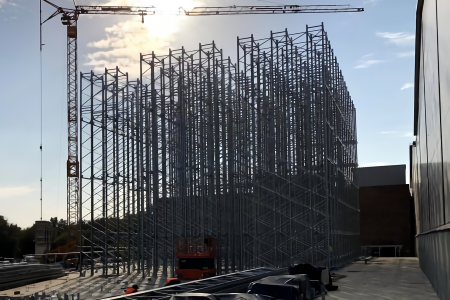

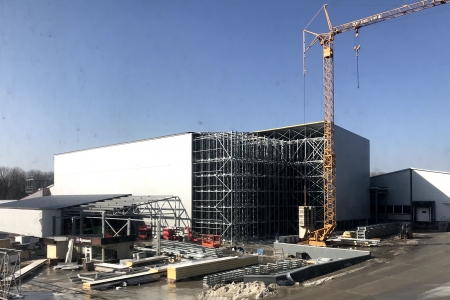

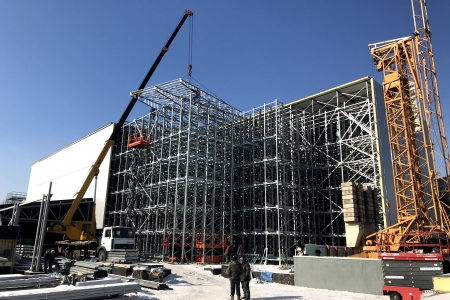

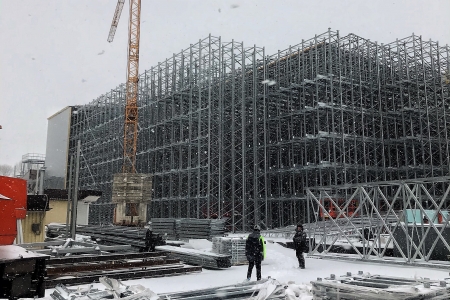

Automatic Storage-Retreval System-Shuttle

Automatic Storage-Retreval System-Shuttle

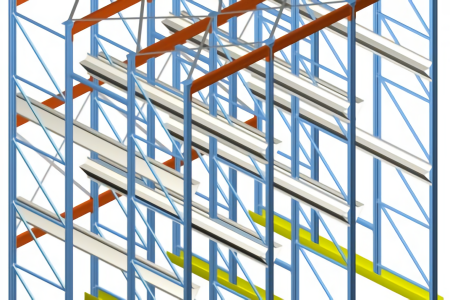

Radio Pallet Shuttle (Semi-Automatic) Racking System is system that is similar to the working principle of the drive-in system, except that loading is done by remotely controlled vehicles called shuttles instead of stacking machines.

There is no need for a corridor as there is no loading with forklift trucks. In this way, it is ensured that the best efficiency is obtained from the area to be installed and the safety of life and material is increased.

The shuttle vehicle, which is placed on the rails on the floor where the loading will be made with the help of the forklift truck, ensures that the pallet is loaded to the desired location and the pallet at the desired location is unloaded according to the commands given on the control.

With Shuttle Loading Rack Systems, the risk of error is minimized and the loading speed is doubled. The main reasons for preference are that the operating costs are greatly reduced and the depreciation period is fast.

It can be designed in 2 different ways, 'First In, First Out' and 'First In, Last Out', depending on the usage.

Advantages;

- FIFO, LIFO

- The ability to work with varying pallet types with the MPS (Multi Pallet Systems) type shuttle.

- Maximum utility from warehouse volume

- Low operation(labor and equipment)cost

- Secure operation ability, since the forklift does not enter the canal.

Heavy Duty Rack Systems

Eren Rack Systems

English

English Türkçe

Türkçe

Teknolojik değişim ve yenilikleri takip ederek, sürekli gelişim ve mükemmeliyeti temel alarak, yüksek kalite standartlarında üretim yapmak, her zaman ve her yerde müşterilerimize en uygun, en kaliteli, en ekonomik ve en doğru çözümleri sunmaktır.

Teknolojik değişim ve yenilikleri takip ederek, sürekli gelişim ve mükemmeliyeti temel alarak, yüksek kalite standartlarında üretim yapmak, her zaman ve her yerde müşterilerimize en uygun, en kaliteli, en ekonomik ve en doğru çözümleri sunmaktır.